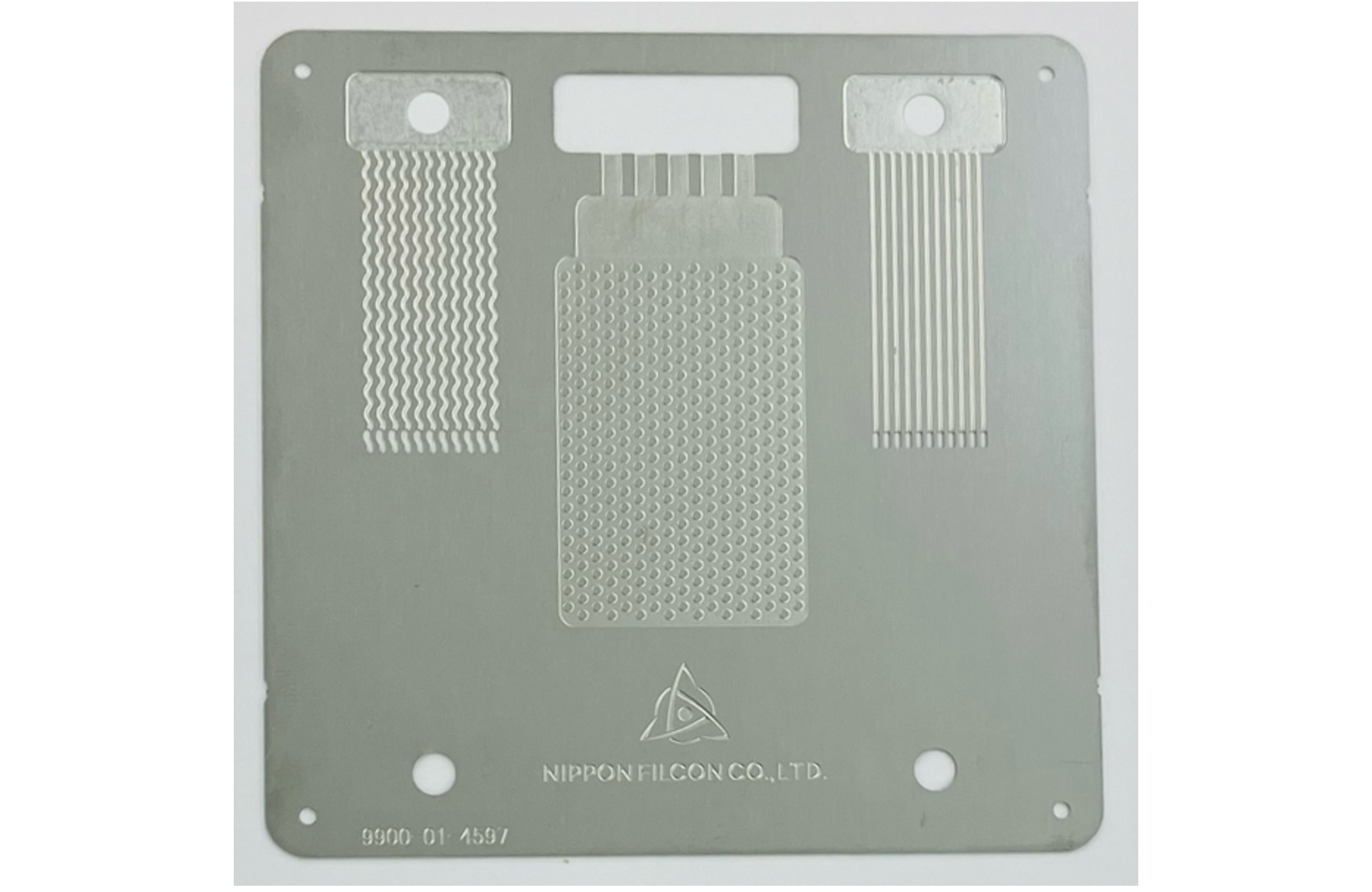

- 1. Overview Of “Ribs (Bridge)”

- In general, during the etching process, multiple ribs are incorporated

to connect the product to the base material during manufacturing. - 2. Why Ribs Are Necessary in Etching Process

In our etching process, ribs are essential to ensure that the product remains

securely connected to the base material during chemical corrosion.

Without these ribs, the product could become dislodged and fall inside

the etching equipment.

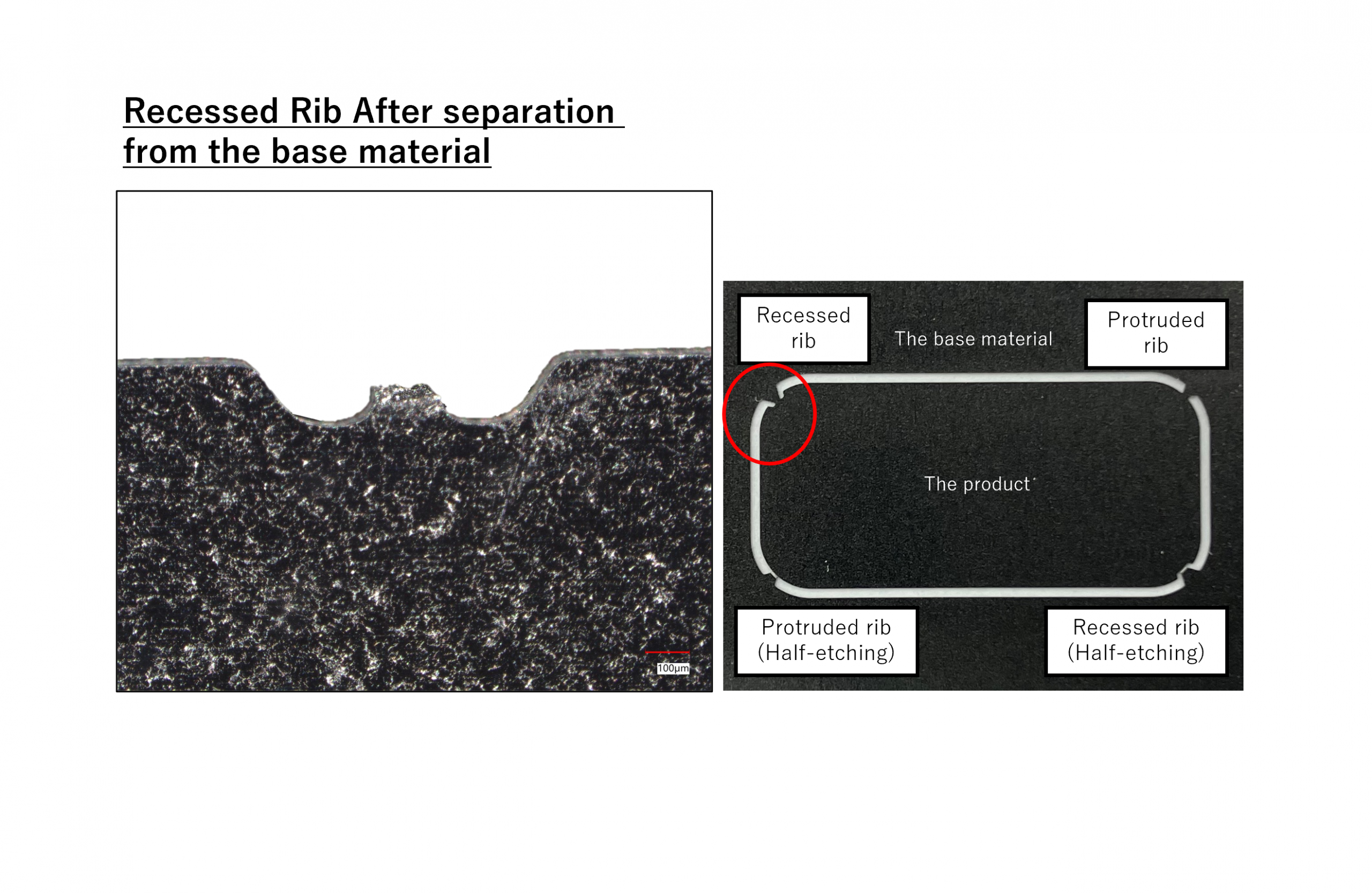

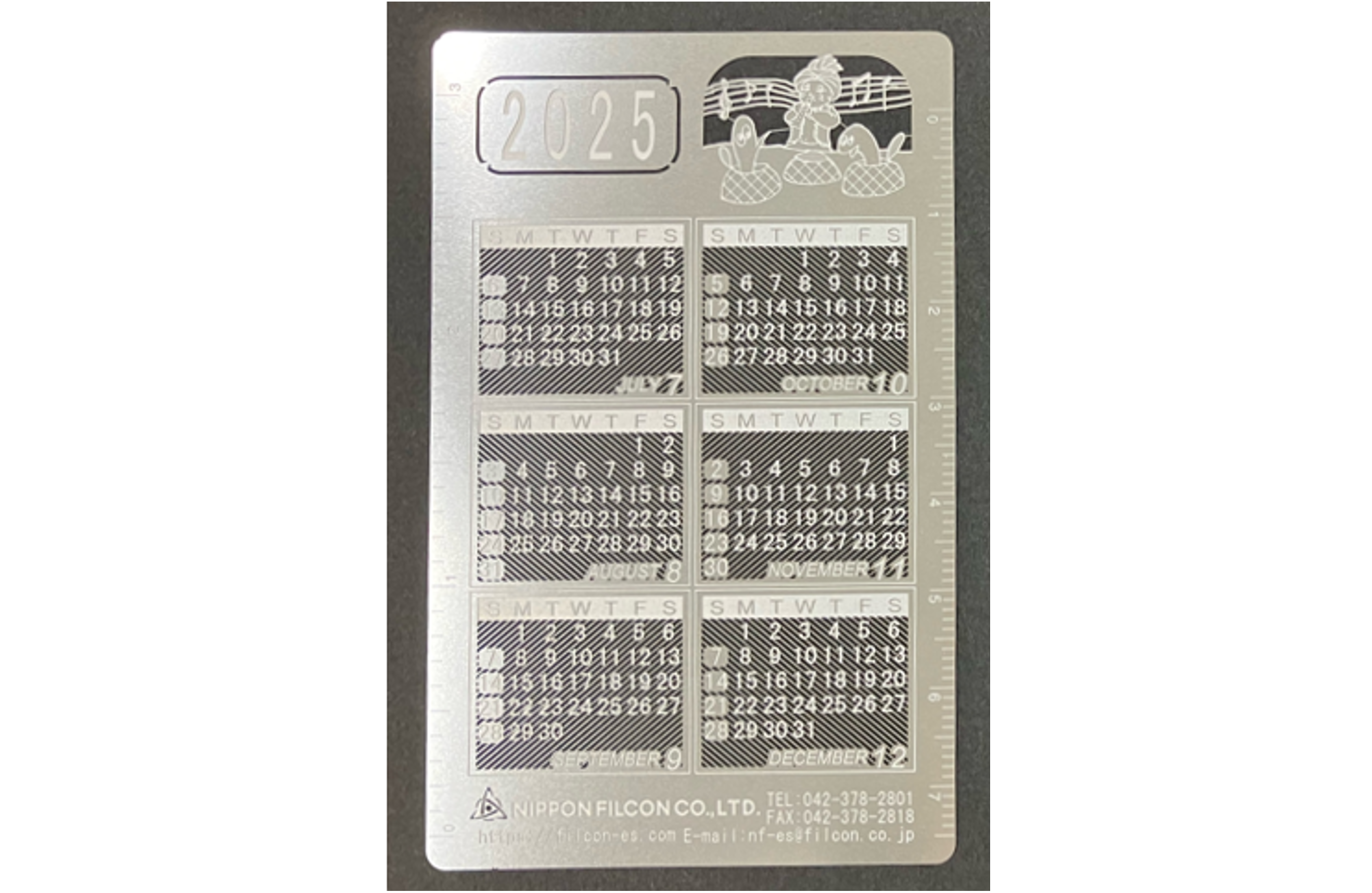

3. Common Effect of Ribs (Bridge Marks)

While etching is recognized for its ability to minimize burr formation,

the use of ribs during processing may result in visible bridge marks along

the outer contour of the product after separation.

*To avoid any protrusion or snagging along the outer edge, recessed ribs

are commonly applied during etching (please refer to the photo.) If you

wish to examine the actual rib dimension, samples can be provided

upon request.

4. Proposal for Rib-Free (Bridge-less) Etching

In case where rib application is not feasible due to design constraints,

we are able to propose a bridge-less etching solution for products with - a thickness of 0.1t or less. Should you be interested, we would be happy to

provide further information or samples upon request.