1. Overview Of Ribs (Bridges)

During typical etching fabrication, several ribs-also known as bridges-are placed to

link the base material with the product.

2. Why Ribs Are Essential in Etching manufacturing

In the etching process, ribs(bridges) are essential to ensure that the product remains securely attached to the base

material during the chemical etching stage, preventing it from dropping inside the equipment.

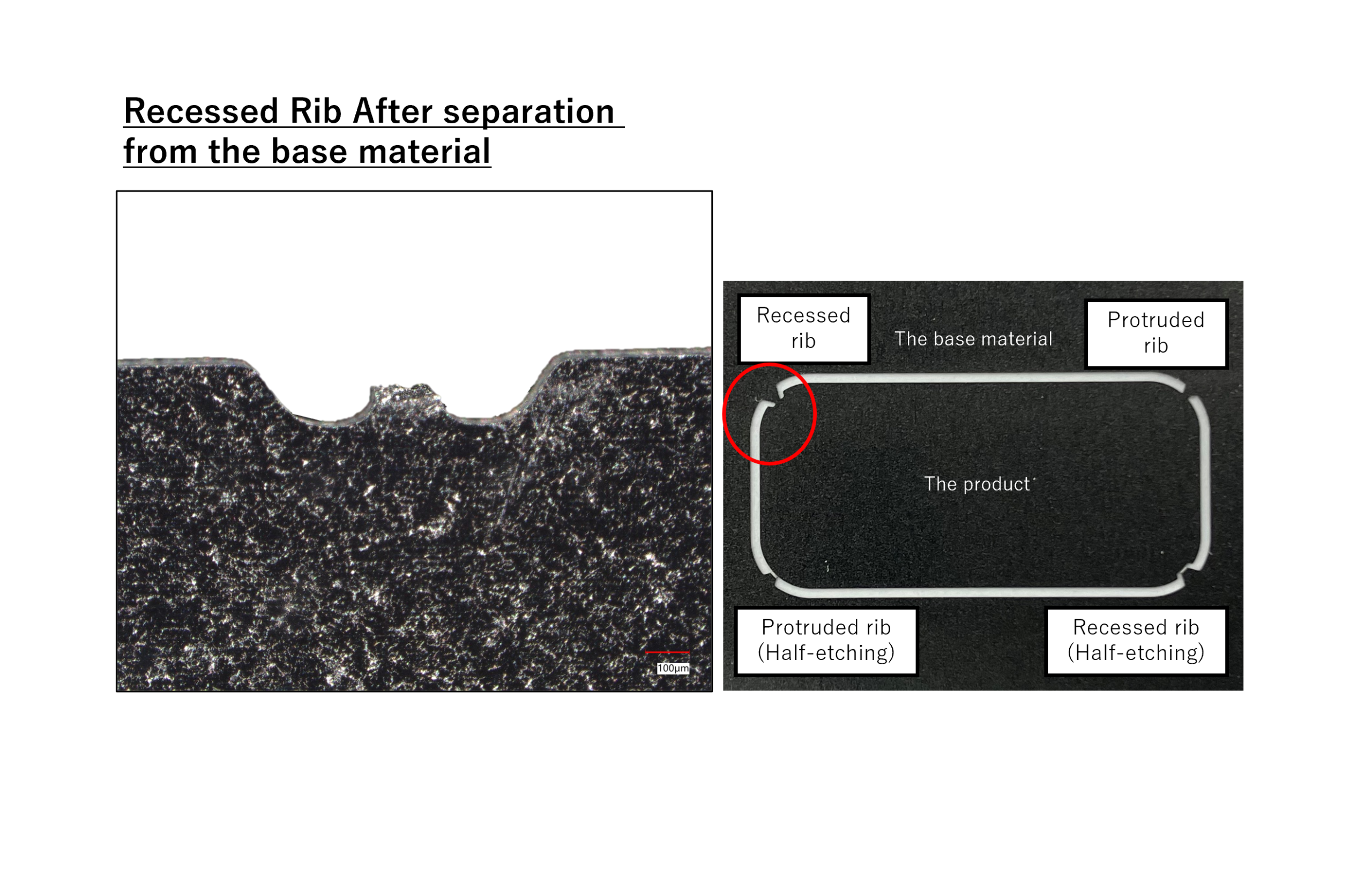

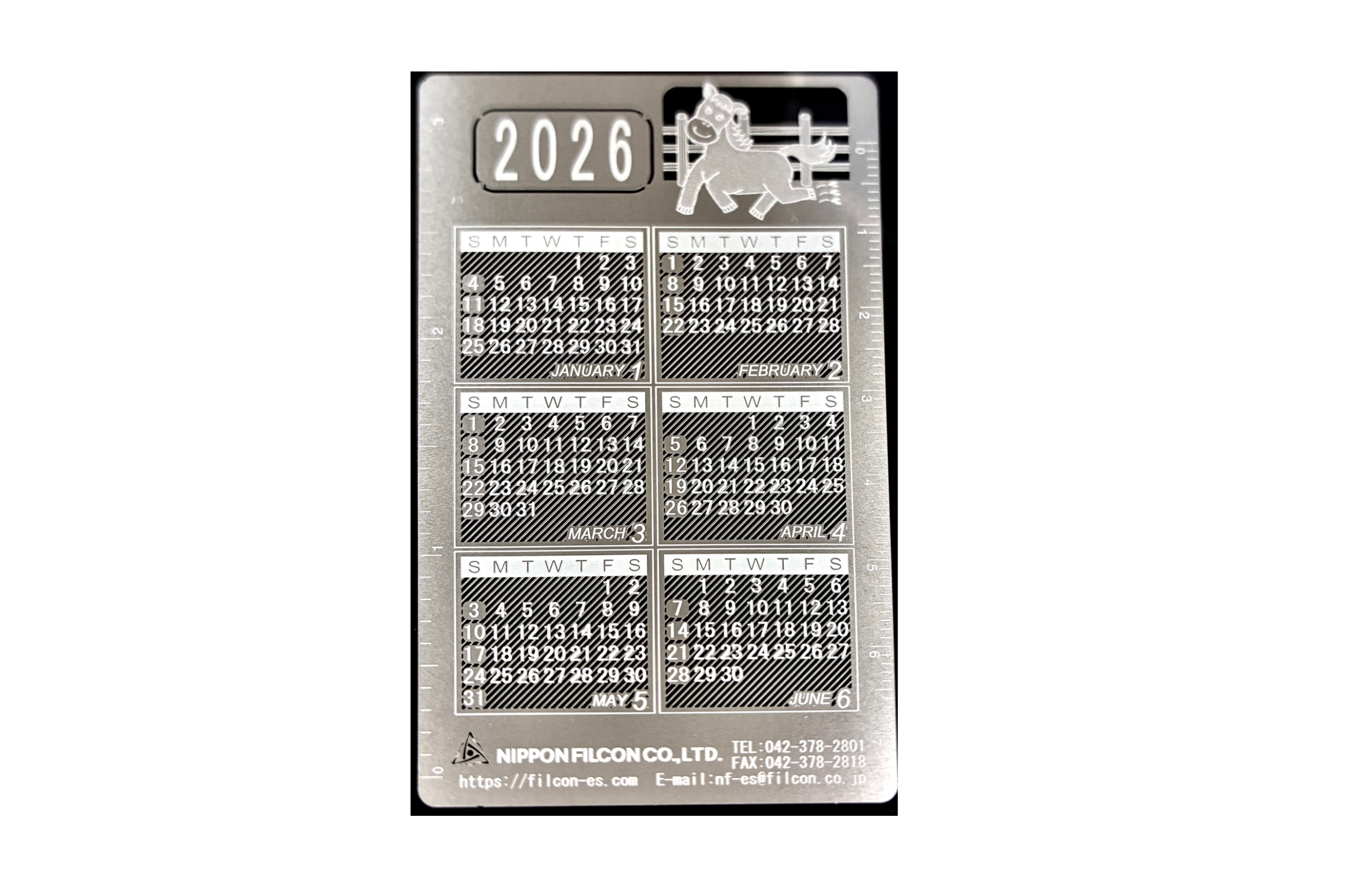

3.Effects of Ribs on the Product (Bridge Marks)

While chemical etching is generally recognized for its low burr formation, the inclusion of ribs (bridges)

during processing may result in bridge marks appearing on the product’s outer contour.

* Recessed ribs are often added to prevent the outer edges of the product from protruding or snagging during handing.

(Please refer to the photo for details.) Samples are available upon request for those who wish

to confirm the actual dimensions of the ribs.

4. Proposal for Etching Without Ribs (Bridge-Free Design)

When ribs cannot be applied due to design constraints, we are able to propose a rib-free (bridge-free) etching

solution for products with a material thickness of 0.1mm or less.