One of the widest size of the CU/PET film’s etching

in Japan!

We undertake the production of composite film etching,

which has contributed to the industry of display by our shield mesh. We will suggest from sheet products to roll products according to our customer’s requests.

Our strength

Clean rooms

We prevent contamination completely because of producing products in clean rooms.

Slit and laminate

We provide mass production at low cost because utilizing our equipment by producing wide size at first and slitting it.

In addition, we can suggest lamination based on our customer’s requests.

Self-supply materials

We have two of CU/PET films.

A small quantity of prototypes is possible to produce,

and we have produced results in shield mesh and electrode for touch panels.

Provided materials by customers

Please feel free to request the processing of Provided materials by customers.

We can produce experimentally small size.

Specification

| Specification | |

|---|---|

| A type of production | Sheet processing, roll to sheet processing, and roll to roll processing |

| Size | 1,250㎜×2,100㎜ at maximum |

| Material | Cu film |

| SUS film | |

| ITO film(Both of amorphous and crystalline materials are available.) | |

| Ag alloy film | |

| Every kind of metal foil+ every kind of resin film(PET,PEN,PI,PC,PEEK,COP and etc.) | |

| Metallic thin film+every kind of resin film | |

| Transparent conductive materials | |

*There’re cases in which materials provided by customers need to be tested in advance.

Secondary processing

| Secondary processing |

|---|

| ・Slit |

| ・Cut(Thomson,Pinnacle,and Plotter) |

| ・Lamination(Multilayer,Flexible Printed Circuits) |

| ・Lamination of adhesive film |

| ・Cu blacking processing |

The examples of products

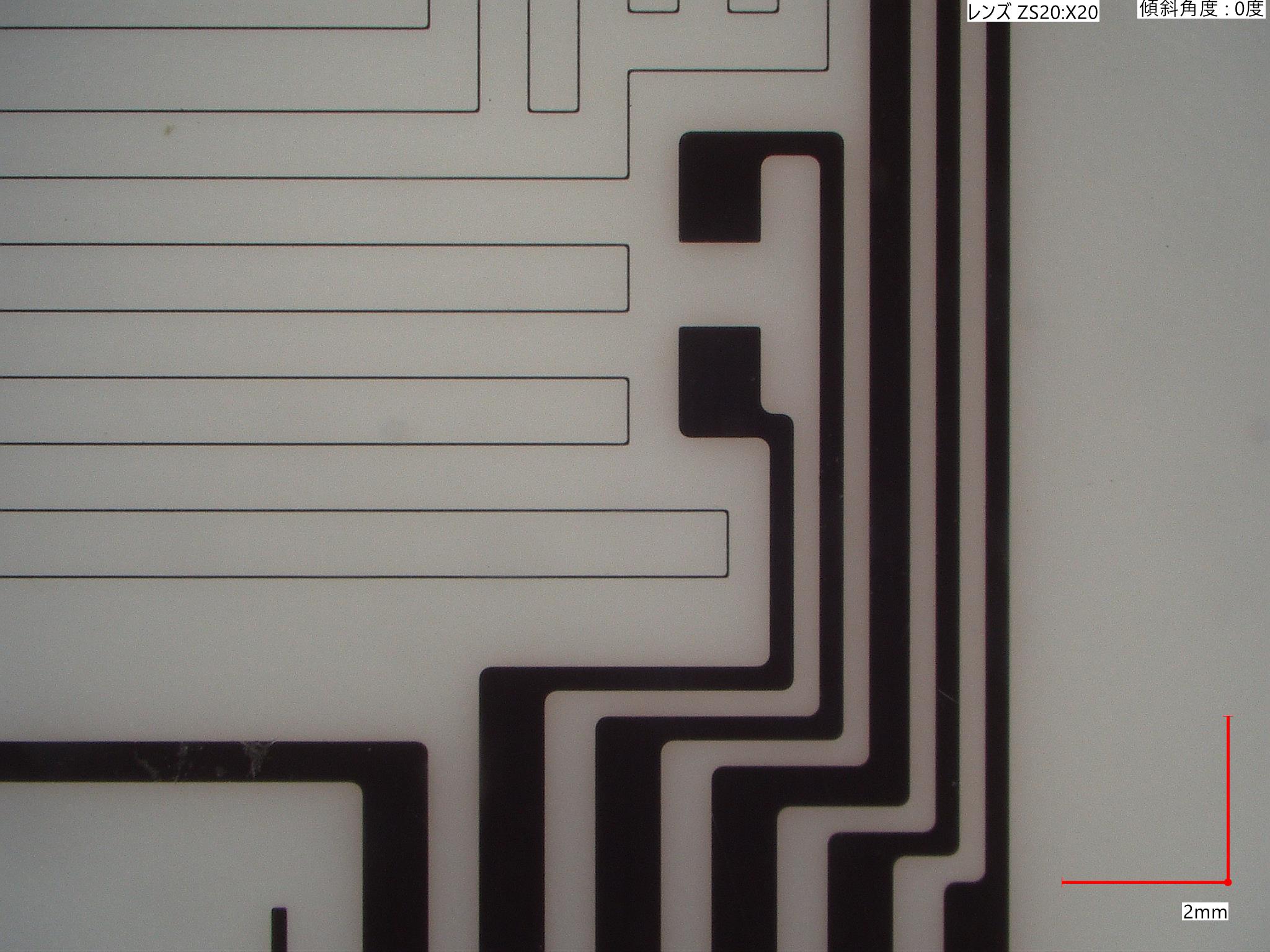

- ・Antenna

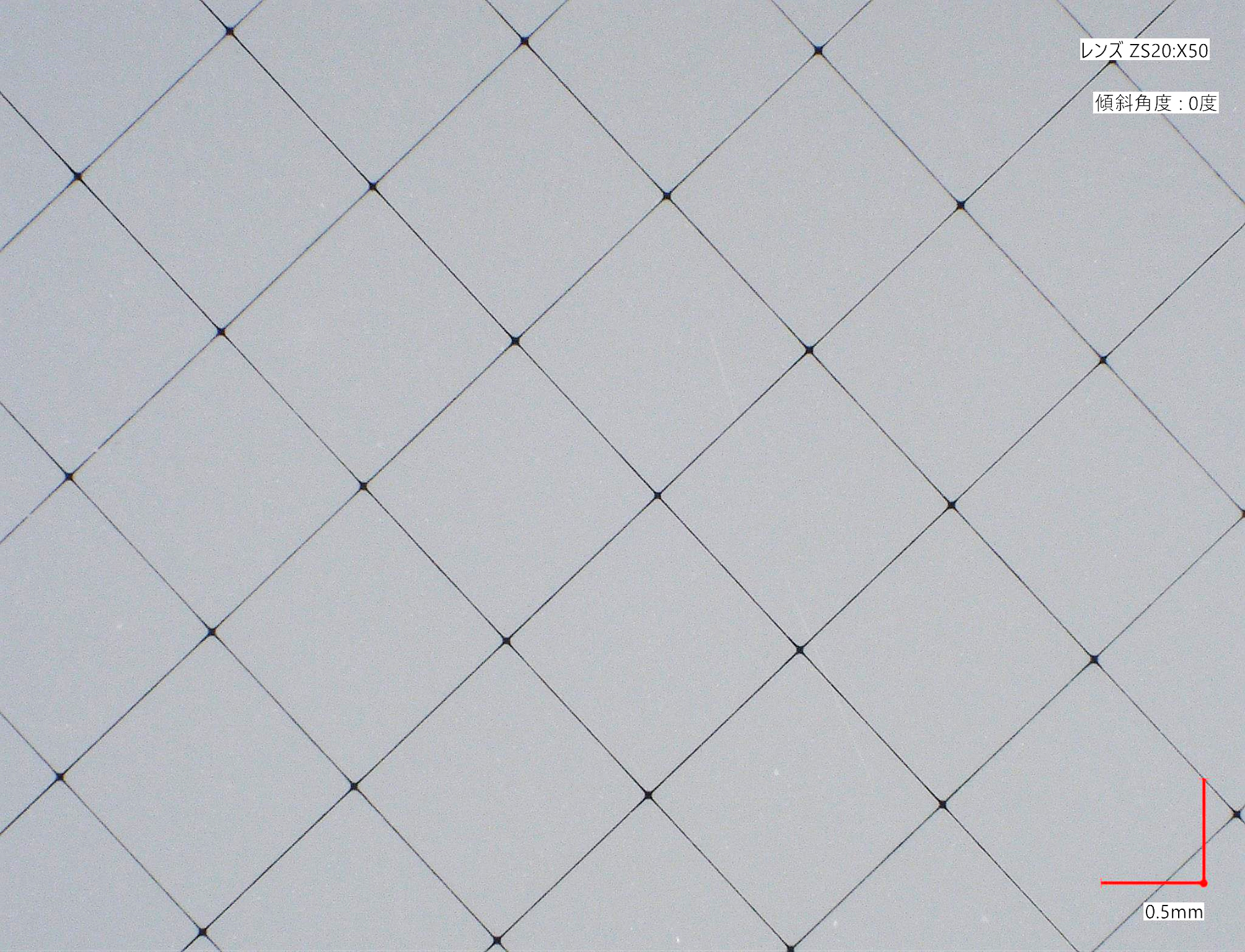

- ・Electromagnetic shield mesh

- ・Electrode for touch panels

- ・Electrode for touch switches

- ・Electrode for transparent displays

- ・Heater

- ・Sensor

- ・Light control film